Beschrijving

SKU: TS-POR-GP-RINGS

TOTAL SEAL GAS PORTED PISTON RINGS

GAS PORTED PISTONS

When it comes to maximizing horsepower in an engine, it ultimately boils down to efficiency. One goal of every internal combustion engine is the seal created between the piston ring and the cylinder wall, especially during the compression and combustion cycles. Instead of trying to overcome the cylinder pressures, why not use it to your advantage?

That’s where gas porting comes in. Gas ported pistons are nothing new. The practice of drilling holes (ports) into pistons to allow the cylinder gas pressures of over 1,800 PSI above the piston to get behind the top piston ring, which helps seal the ring against the ring groove and cylinder wall, has been around at least since the 1970’s.

GAS PORTED RINGS

Lateral and vertical gas ports apply added pressure to the rings at several fixed locations depending on where the ports are drilled into the piston. The tradeoff of using gas ported pistons is increased cylinder bore wear in areas corresponding to where the gas ports are located in the pistons. Depending on where the gas ports are machined, this machining can weaken that area along with the ring land itself. As a result, we’ve typically only used gas ported pistons on race engines that will be torn down and rebuilt after a fixed number of hours. Additionally gas ports can quickly get plugged by carbon that render them useless.

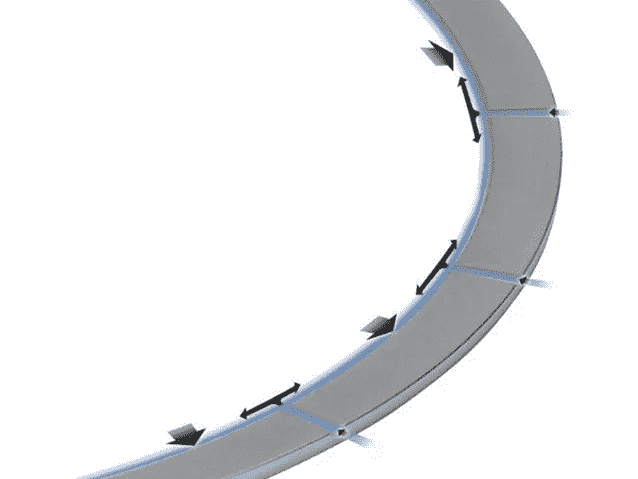

What is new are gas ported piston rings. Both gas ported pistons and gas ported rings allow gas pressure above the piston to get into the ring groove and exert outward and downward force on the piston ring itself. Total Seal’s Gas Ported Rings feature unique horizontal slots machined into the top of the ring. These slots direct combustion gases to a bevel behind the ring to push the ring out towards the cylinder wall and improve the seal. This technology stems from the use of gas ported pistons which have been available for a number of years, yet porting the pistons has a number of downfalls. Instead of drilling holes into the piston, slots are cut into the piston ring. As the top ring rotates in the piston during normal operation, using a gas ported top ring allows for even cylinder bore wear. An added benefit over gas ported pistons is that the gas ported ring is self cleaning and doesn’t get plugged with carbon. Rather than weakening the piston, adding gas ports to the top ring makes the most sense. Total Seal Gas Ported Top Rings can be made from ductile iron, carbon, or stainless steel and can include wear resistant PVD coatings for long-lasting performance. This makes a gas ported top piston ring the logical choice where improved ring seal is desired in a high performance Porsche street or race engine rebuild.

The extra force increases ring seal and reduce blow-by, which in turn should increase engine efficiency which means more horsepower. This is especially important in an aircooled Porsche engine, as aluminum cylinders grow significantly as the engine warms up. Gas ported rings should provide even and consistent pressure for the ring against the cylinder bore, resulting in faster break-in and better ring seal for Porsche engines with Nikasil bores, especially when paired with Total Seal’s Total Conform or Gapless ring technology. Just like the Total Seal Gapless top and second piston rings we have used and recommended for years with our Nickies cylinders and JE, CP, or Mahle Motorsports pistons, we expect great things from engines fitted with Total Seal’s Gas Ported Top Rings.

CUSTOM TOTAL SEAL GAS PORTED PISTON RINGS FOR PORSCHE ENGINES

LN Engineering offers custom Total Seal Porsche piston ringsets for all aircooled and watercooled Porsche engines including Total Seal Gas Ported and Total Conform piston rings. If it takes a piston ring, Total Seal can make it!