Beschrijving

KIJK HIER DE AFLEVERING VAN WHEELER DEALERS

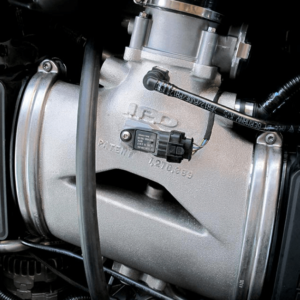

IMS-OPLOSSING ALS PREVENTIEF ONDERHOUD:

IMS-vervanging duurt gemiddeld 10-14 uur en vereist dat de transmissie wordt verwijderd. Voor de Tipronic 911-modellen moeten de motor en de transmissie als een complete eenheid worden verwijderd om de motor en de versnellingsbak te kunnen scheiden.

Meestal gekoppeld aan koppeling en ander onderhoud zoals vervanging van RMS, AOS, waterpomp, vliegwiel met dubbele massa, enz.

Als er een motorstoring optreedt, duurt het opnieuw opbouwen meer dan 60 uur en kan het tienduizenden dollars kosten om het op te lossen. Als het IMS-lager eenmaal begint te falen, kan het niet veilig worden vervangen, omdat versleten metaal van het originele lager het vervangende lager of andere interne motoronderdelen kan beschadigen.

Motoren moeten vooraf worden gekwalificeerd voordat de lagers worden vervangen.

Ga voor meer informatie over prekwalificatie naar https://lnengineering.com/products/ims-bearing-installation-tools/ims-pre-qualification.html

HOE INSTALLEER JE DE IMS SOLUTION?

Download IMS Solution Installation Manual

Download IMS Solution Installation Manual

WELKE FABRIEKSLAGER HEEFT MIJN MOTOR?

1997-1999: Deze motor had een IMS met twee rijen lagers.

2000-2001: Deze motoren kwamen uit de fabriek met een dubbele rij of een enkele rij IMS-lagers. Een enkele rij flens is 19,27 mm diep en een dubbele rij flens is 13,34 mm diep.

2002-2005: Deze motor had een IMS-lager met één rij. Sommige modellen uit de late productie van 2005 hebben een niet-onderhoudbaar IMS.

2006-2008: Deze motoren zijn uitgerust met een groter lager, gemakkelijk te herkennen aan de 22 mm centrale moer, die niet kan worden gerepareerd zonder een volledige demontage van de motor. Het verwijderen van de IMS-lagervetafdichting zorgt voor een goede smering van het originele lager.

Als de motor in uw auto is vervangen, heeft deze het IMS-lager dat in productie was voor dat modeljaar van fabricage voor de vervangende motor.